For Monitoring Process Capability We Use Which Graph

In simple words it measures producers capability to produce a product within customers tolerance range. X-bar represents the average value of the variable x.

3 4 6 Assessing Process Capability

It is expressed as a process performance index P p.

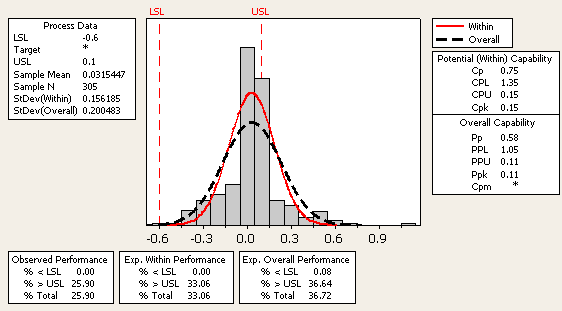

. Displays the statistics commonly used to report on process performance. It does not track anything else about the measurement such as its. It checks whether it is meeting customer requirement or not.

See Understanding capability measures for a discussion comparing statistics measuring long-term LT and short-term ST performance. It varies from Process Capability in the fact that Process Performance is applicable to a particular batch of material. Cpk stands for the Index.

Process Capability Index Cpk. Use an R chart to monitor the variation of a process and determine whether it is stable enough to perform capability analysis. This often happens with a mature process that has been around for a while.

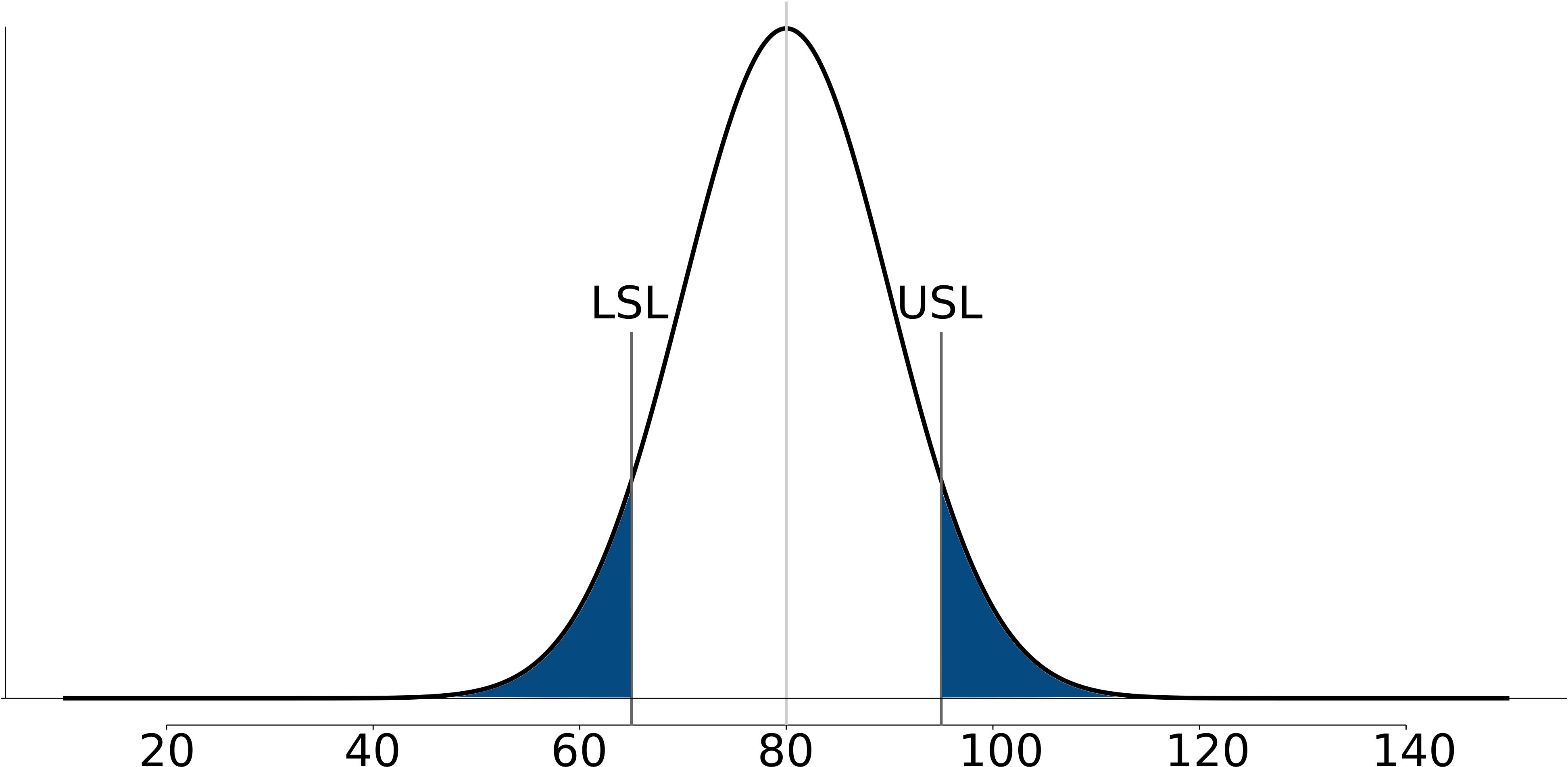

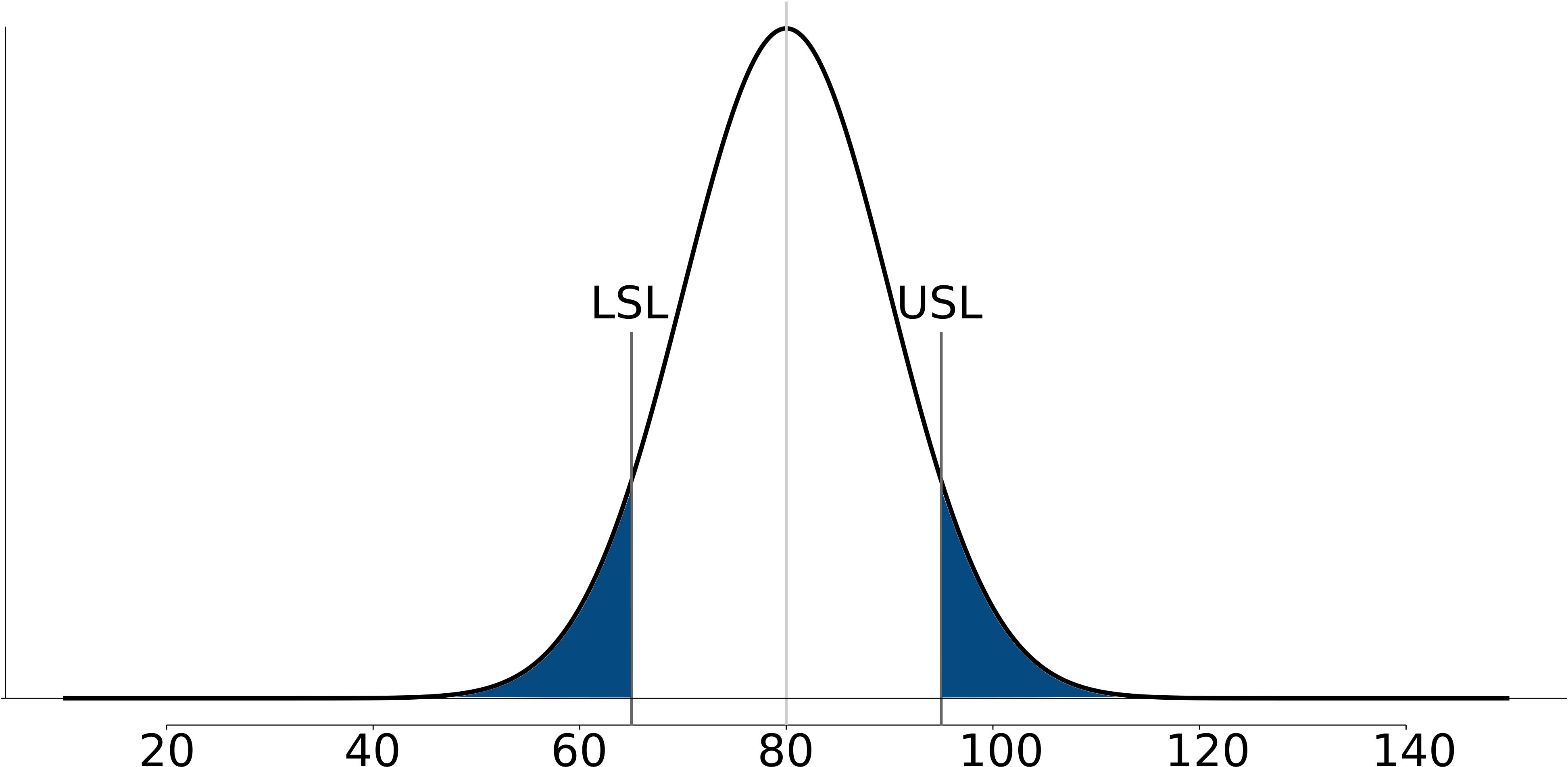

This is illustrated in the graph below. The charts are selected based on different two factors. Use a capability chart.

Process capability uses the process sigma value determined from either the Moving Range Range or Sigma control charts. Goal Plot Graph for quickly assessing how processes are conforming to. Cpk is used to estimate how close you are to a given targe.

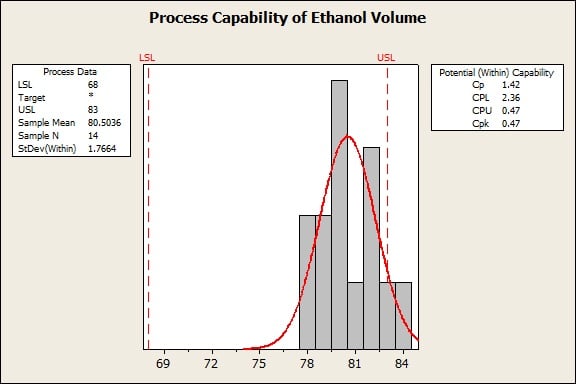

When used to monitor the process control charts can uncover inconsistencies and unnatural fluctuations. Cp and Cpk are used for Process Capability. When you will open the Minitab 18 the main screen will appear like below.

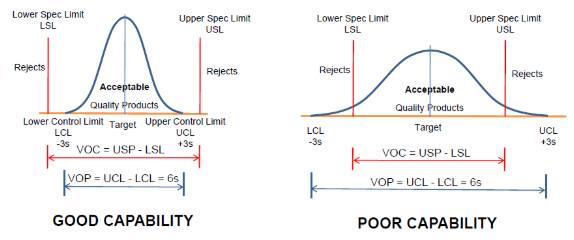

Monitoring charts We use monitoring charts also called control charts to display and detect this unusual variability. This can be represented pictorially by the plot below. There are several statistics that can be used to measure the capability of a process.

We have also adopted six sigma as the goal for performance acceptability. P-charts are used to determine if the process is stable and predictable as well as to monitor the effects of process improvement theories. USL-Average of Mean3 x Standard Deviation 80-7143 3 x 092 857 276 310.

Most capability indices estimates are valid only if the sample size used is large enough. 2 subgroup size. A Shewhart chart named after Walter Shewhart from Bell Telephone and Western Electric monitors that a process variable remains on target and within given upper and lower limits.

Capability indices predict process behavior. We will not use the term SPC rather we will use the term process monitoring. The X-bar and R chart is one of the most widely used charts for variable type.

It is a monitoring chart for location. If a point is out of the control limits it indicates that the mean or variation of the process is out-of-control. Process capability index Cpk is a statistical tool to measure the ability of a process to produce output within customers specification limits.

The concept of six sigma was developed in industry as a. The larger the Cp index is the less likely it is that any unit manufactured in your process will be outside the defined limits. This is an example of.

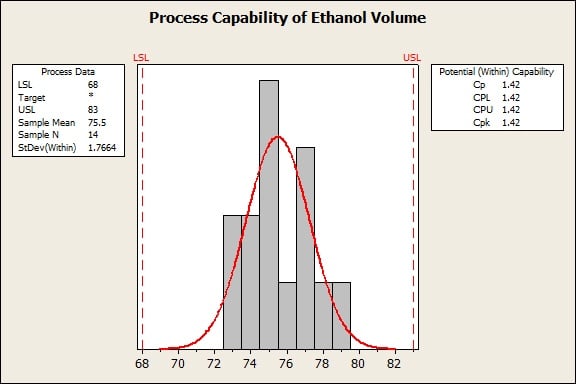

Cpk 310 minimum of CPU or CPL. A process where almost all the measurements fall inside the specification limits is a capable process. Graphically we assess process capability by plotting the process specification limits on a histogram of the observations.

The subgroup would vary depending on the total number of claims each week. Generally you use this when a process is under statistical control. Average of Mean-LSL3 x Standard Deviation 7143-60 276.

Process Capability Cp. Cpk Process Capability Index 166. After stabilizing the process at Blanking operation.

USL-LSL 6 x Standard Deviation 80-60 6 x 092 20552 361. Consequently SPC charts are used in many industries to. If the histogram falls within the specification limits then the process is capable.

Although statistical process control SPC charts can reveal whether a process is stable they do not indicate whether the process is capable of producing acceptable outputand whether the process is performing to potential capability. Process Performance Graph Four quadrant graph that assesses processes in term of stability and capability. Lets get started with an Example A sheet metal manufacturing company was producing Brake pad.

To understand what a process is doing and what it can do we need both the Cp and Cpk indices. If data has been collected in this way the standard method for performing capability analysis is used. C_p C_pk and C_pm.

The R chart indicates whether the subgroup-to-subgroup variation is in control. Note how the process is shifted below target and the process variation is too large. Red points indicate subgroups that fail at least one of the tests for special causes and are not in control.

1 the data is attribute or variable. In our laboratory we tailor the control algorithm for individual assays based on the capability of the analyte 4 and use a combination of assay capability and the multirules to monitor analytical performance. Control Chart Selection in SPC.

Statistical Process Control charts graphically represent the variability in a process over time. Process performance works to check the conformance of the sample generated using the process. It refers to how well the process can satisfy the specifications.

Minitab Process Capability Tutorial Step by Step guide. Capability Cp and performance Cpk indices go beyond elemental quality control to illustrate a processs ability to meet specifications. A direct way to measure and make an analysis of the process capability.

They represent the fit between the expected future production and the specifications. A monitoring chart is a display of one value variable against time or. Pp and PPk are used for Process Performance.

The length of the Brake pad was 1501mm. Use the ZBench values to describe process performance. Using the graph we can further evaluate process capability by comparing the spread or range of the product specifications to the spread of the process data as measured by Six Sigma process standard deviation units.

There are two ways to collect data for capability analysis. The control limits on both chats are used to monitor the mean and variation of the process going forward. The standard method is from a control chart where the data is collected over a period of time.

It measures how close your process is to the defined upper and lower limits compared to a reference optimal process. Cp Process Capability 168. For example use a p-chart to plot the proportion of incomplete insurance claim forms received weekly.

The x-bar and s-chart are quality control charts used to monitor the mean and variation of a process based on samples taken in a given time. Cp is the process capability. It answers the question whether the variables location is stable over time.

3 8 Process Capability Process Improvement Using Data

Process Capability Statistics Cp And Cpk Working Together

Cp Cpk Pp And Ppk Know How And When To Use Them

Illustration Of Process Capability Index Parameters In Eq 2 T 78 Download Scientific Diagram

Cpk Distribution The Fact Underlying Process Capability Indices Part Ii Application Ivt

Getting The Most Out Of A Capability Analysis

Cp And Cpk Statistics Process Capability Analysis Infinityqs

How To Measure Process Capability And Process Performance

Process Capability Quality One

6 1 6 What Is Process Capability

Process Capability Part 1 Bpi Consulting

Step 4 Interpret The Graph Pattern And Cpk Value Process Capability Statistical Process Control Excel Templates

Process Capability Cp Cpk And Process Performance Pp Ppk What Is The Difference

Cp Cpk Pp And Ppk Know How And When To Use Them

Process Capability Statistics Cp And Cpk Working Together

What Is Process Capability Spc 101 Infinityqs

Cp And Cpk Statistics Process Capability Analysis Infinityqs

Comments

Post a Comment